Production part

Description

The production part is a part roll and contains the relevant production data. This module is used to maintain production parts.

A new production part can be created in two ways:

- From the input window of the parts master via menu item

- New button in the editing / list window of the production part

If the production part is called up from the input window of the part master, the system first checks whether a roll of this type already exists and displays it if necessary. Otherwise a new production part is created and connected to the part master (only after saving). On the tab 'Production data' the data from the part master are taken over, which must be supplemented by the missing points.

With the second option, a new part master record is created for the production part when saving, which you should maintain afterwards.

A production part can be defined as a normal assembly (part has a bill of material and routing), factory assembly (part has no bill of material, only a routing), MRP assembly (the production part has its own MRP bill of material and is only defined from a logistics point of view) or engineering assembly (the part is not "seen" from a logistics point of view).

Functionality

Input window

You can select a production part by entering the desired number in the Number field and confirming with RETURN. If you want to open the list window, you can select the menu item "Search".

This window is divided into the different flaps

| Menu item | Description |

|---|---|

| Edit | - |

| Part | Call up the input window of the part master |

| : Specific search terms | - |

| : : General | Search terms also apply to the part |

| : : Roller-bound | Search terms only apply to the production role |

| : Search terms | - |

| : : Insert | Insert search term |

| : : Remove | Remove search term |

| : parts list | - |

| : : Select and assign existing master parts list | Selecting the parts list of the production part |

| : : : Create and assign new master bill of materials | Creation of the parts list of the production part |

| : : Edit assigned master bill of material | Change the parts list of the production part |

| : Work plan | - |

| : : Select and assign existing master work plan | Selecting the routing of the production part |

| : : Create and assign new master work plan | Creation of the work plan of the production part |

| : : Edit assigned master task list | Change the routing of the production part |

| : Features | - |

| : : Insert | Inserting a feature |

| : : Edit | Editing a feature |

| : : Remove | Removing a feature |

| : Specifications | Specifications are combinations of characteristics stored in the form of specification numbers for which the preliminary costing is to be carried out automatically. |

| : : Edit | Manual editing of the specifications via the corresponding mask |

| : : Delete | Deleting all stored specifications |

| : : Generate (from subparts list) | The specifications can be automatically stored using the subparts list of the variant part |

| : Validity | Set validity |

| Close | Close window |

| Search | Call up list window |

| Options | Call up the option window |

| Menu item | Description |

|---|---|

| Archive selected entries | The status of the selected preliminary cost estimates is set to "archived", which means that they are no longer displayed in the list of preliminary cost estimates for the production part by default. In order to be able to see these cost estimates as well, activate the check mark "Show all preliminary cost estimates" above the list |

| Create cost table from selected entries | - |

| : Existing, valid price table, extend according to predefined columns | The characteristics that are present in the prepared, empty price table are determined by the marked preliminary costing and for each preliminary costing a price table entry with its corresponding characteristic value is created for all predefined characteristics. The preliminary costing is then given the status "accepted" and the acceptance date and the editor are saved. (All pre-calculations are recalculated during this action so that manually adjusted values of parts are also taken into account. Therefore this process may take a little moment). Attention: Prerequisite for this is the previous creation of a price table with defined object characteristics (columns)! |

| Copy valid price table and create new table according to its columns | The previously valid price tables for material and wages are copied and emptied. The functional characteristics which were previously valid in the valid price table are determined by the marked preliminary cost estimates and for each preliminary cost estimate a price table entry with its corresponding characteristic is created. The preliminary costing is then given the status "accepted" and the acceptance date and the editor are saved. (All pre-calculations are recalculated during this action so that manually adjusted values of parts are also taken into account. Therefore this process may take a little moment). Attention: Prerequisite for this is that the previously valid price table contains defined functional characteristics (columns)! |

| Existing, valid price table, synchronise with selected items | No new price table is created, but the existing one is supplemented by newly added or changed entries. Prerequisite is a valid price table of material and labour costs. |

| Create a new table from selected entries fully automatically | All the characteristics that are available in the preliminary cost estimate and their lot size are determined by the selected preliminary cost estimates and for each preliminary cost estimate a price table entry with its corresponding characteristic. The preliminary costing is then given the status "transferred" and the transfer date and the processor are saved. (All preliminary calculations are calculated again during this action so that manually adjusted values of parts are also taken into account. Therefore, this process may take a short moment ). Price tables for non-global overhead costs are also created! Attention: It is NOT a prerequisite to create the tables first! |

| Set transfer indicator on selected entries | Manually set the identifier that the selected preliminary costings have been transferred/considered as costs in the production part |

| Create preliminary costing | |

| : Manual embossing | A new parts preliminary costing object is created in the Parts preliminary costing module. However, the preliminary costing is not yet started automatically in order to be able to specify lot size, characteristics, etc. |

| Copy select preliminary costing | A transient or persistent copy of the preliminary costing is created in the Parts preliminary costing module. However, the preliminary costing is not yet started automatically in order to be able to specify lot size, characteristics, etc. |

| Automatic for all specifications | If specifications are stored on the production part, part pre-calculation objects are automatically created for each of these characteristics. However, the preliminary costing is not yet started automatically in order to be able to specify lot size, material characteristics, etc. |

| : Manual from specifications to be selected | If specifications are stored on the production part, those can be selected beforehand for which part pre-calculation objects are to be created. However, the preliminary costings are not yet started automatically in order to be able to specify lot size, characteristics, etc. |

| Symbol | Description |

|---|---|

| The input window is cleared. |

| Changes to the production part are saved. |

| Delete production part |

| Printing the window content |

| Create/edit notes |

| Call up the maintenance mask of the part |

| Call up the maintenance mask of the parts list of the production part |

| Call up the maintenance mask of the routing of the production part |

| Display of all operations of the production part |

| Set validity |

| Copy pre-calculations to the clipboard / Print report |

| Show parts usage |

| Field | Description |

|---|---|

| Production data | |

| This is where the most important data on the production of a part are kept. Central here are the parts list and the work plan. | |

| : number * | Production part number. This can be different from the part number in the part master. This is a mandatory field! |

| : Search terms | Search terms of the production part (see also menu "Specific search terms"). |

| : Description * | Description text of the production role. This description can/should be different from the part master text in order to highlight production-specific characteristics. This is a mandatory field! |

| Part * | Reference to the part of the production part: the production part data is partly modelled as a role |

| : Operating assembly | Indication whether it is a production part that does not itself have/needs a bill of materials: these can be parts that are either only further refined by a work plan or parts whose material itself consists only of manual stock or of auxiliary or operating materials. This option is only useful for parts that are part of another BOM and therefore not a level 0 part. This information is particularly required for a part precalculation, as otherwise a production part without a BOM will lead to a termination there. This specification can only be set if no BOM or MRP BOM is specified. |

| : parts list | Reference to the parts list of the production part. |

| : Dispositive product structure | Description of dispositive assembly If a bill of material is linked in a production role and an entry exists in the MRP product structure, the specified part is "pushed" on the entry of the MRP product structure below the production part when the production bill of material is exploded. All parts which are specified in the bill of material item list on the purely MRP assembly are thus moved from higher-level bill of material levels below the new entry. Only one valid MRP product structure (MRP assembly) can be created. It is possible to assign a formula to individual entries. If the formulas are so different that only one valid MRP assembly is found for each purpose, multiple entries are also possible. Further technical information and instructions for creating an MRP assembly as a variant bill of material. |

| : : Constructive assembly | Identification whether the production part is generally to be managed in a parts list as a constructive assembly (constructive assembly). If a part is placed in a master BOM, this identifier is also transferred to the master BOM item. If you want to change these identifiers subsequently, you can do this via a special service of the parts usage module. This identifier cannot be set if a) the part is not a production part, b) the part has no BOM, or c) the part is managed as a stock item. If the part is a dispositive variant part to be produced without its own BOM (i.e. each sub-part has its own BOM), then only a warning is issued: in the course of a BOM explosion, any replaced sub-part would then be treated as a constructive assembly. |

| : Work plan | Reference to the work plan of the production part. |

| : Batch size | Quantity that is offered as a production quantity by default. For certain parts it is not worthwhile to manufacture them individually, as the set-up times would be too long. For this reason, several of some parts are always built at once. This lot size is entered in stock orders (warehouse orders) as a quantity proposal. |

| : Lead time | Rough lead time of the part in production. This should not be less than the sum of the lead times in the routing (after resolution). Serves as a first rough estimate for the production of the part without having exact knowledge of the work plan. In contrast to the replenishment time (see below), only the production time of the part itself is meant here - without its assemblies, i.e. also without the procurement time of sub-parts, which can be quite longer. |

| : : Determine maximum lead time from work sequences | The throughput times (days) are added from all work sequences of the work plan referenced on the production part. For conditional items, the longest lead time is used. After pressing this button, the calculated lead time is already entered in the field, but not automatically saved. This lead time is only a suggestion and must be confirmed by subsequently saving the production role. Attention: This button is only visible if the type of lead time is set to "Value". |

| : reloading time | The replenishment lead time is the lead time + the largest replenishment lead time of all disposable subparts of the first stage. Time required to manufacture the part, including replenishment times of all disposable subparts. Corresponds to the replenishment time of an ordered part (see also Lead time field). |

| : : Determine maximum replenishment time from all MRP subparts of the referenced BOM. | The replenishment lead time is the lead time + the largest replenishment lead time of all disposable subparts of the first stage. The longest replenishment lead time is determined from all MRP BOM sub-items of the BOM referenced at the production part and added to the own lead time. The batch size of the production part is used for the calculation. For conditional items, the item with the longest replenishment lead time is used. After pressing this button, the calculated replenishment time is already entered in the field, but not automatically saved. This replenishment time is only a suggestion and must be confirmed by subsequently saving the production role. Attention: This button is only visible if the type of replenishment time is set to "Value". |

| : : Planning supplement | Enables an additional buffer time to be defined for the backward date calculation if the procurement time is determined dynamically. An additional waiting time is defined for the part and the start date is shifted forward by the value. |

| : Logistics * | The logistics indicator. This field is only available for manufacturing services. This is a mandatory field! |

| Features | |

| On the 'Characteristics' card, you can define characteristics for the production part. This list defines the material characteristics to be taken into account in production (e.g. proof on the working papers). | |

| : Create | Create a new local attribute. |

| : Insert | Inserting a feature from the master list of features. |

| Remove | Remove the item selected in the list. |

| Costs | |

| The 'Costs' card allows you to enter the material and wage costs. | |

| : Cost categories | Indication of the cost element for posting the costs incurred in producing the part. |

| Material | Standard or even planned costs of the material used for the part. |

| : : Variable costs | Indication of the variable material costs for the part. The variable material costs can be displayed via the button |

| : : Overhead costs | Indication of the overhead costs of the material used for the part. These could also have been stored in the client. The overhead costs can be displayed via the button |

| : : Material Total | Summary of the variable and overhead costs of the material. The total material costs can be displayed by clicking on the button |

| : : Allow zero material costs | This checkbox can only be selected if the material costs are zero. Normally, production parts without material costs are not recorded in the final costing. These are recorded as batch errors and can be displayed and corrected. If this checkbox is selected, the labour costs are posted in the final costing without generating a batch error. If the material price is conditional', the checkbox is automatically deactivated. Material or labour costs must be available, both cannot be zero and can be posted to the post-calculation without batch errors. |

| : Wage | Standard or planned costs of the production hours used for the part. |

| : : Variable set-up costs | Indication of the variable set-up costs. The variable setup costs can be displayed with the button |

| : : Variable costs | Indication of the variable labour costs for the part. The variable labour costs can be entered via the button |

| : : Overhead costs | Indication of the overhead costs of the production hours used for the part. These could also have been stored in the client. The overhead costs can be displayed via the button |

| : : Total set-up costs | Indication of the set-up costs before the production of the part can be started. The set-up costs can be displayed via the button |

| : : Total wages | Summary of the variable overhead and set-up costs of the wage. The total wage costs can be displayed with the button |

| : : Allow wage costs to be zero | This checkbox can only be selected if the labour costs are zero. Normally, production parts without labour costs are not posted in the final costing. These are recorded as batch errors and can be displayed and corrected. If this checkbox is selected, the material costs are posted in the final costing without generating a batch error. If the wage price is conditional', then the checkbox is automatically deactivated. Material or labour costs must be available, both cannot be zero and can be posted to the post-calculation without batch errors. |

| : Sums | The bare sum of material and wage costs WITHOUT surcharges |

| : : marginal costs | Marginal cost is the sum of the variables wage and material costs. (Overhead costs are not included here). |

| : : Preliminary costing | Marginal cost is the sum of wage and material costs including overheads. |

| : : Production costs | The costs allocated to production overheads. |

| : : per date | Date of entry of the costs. |

| : : Test value | If the costs are conditional costs, attributes with test values can be added to the "Sum" group. These values are saved at the production part, so that all data do not have to be re-entered when called up again. Using the context menu, attributes can be inserted and removed, and automatically transferred from the part. The test values also influence the subtotals (material -, total wages). Here too, the costs are marked as "Determined costs" if they depend on variables (formula, table). |

| Documents | |

| : Structure tree | Using the structure tree on the left side, subfolders or subnodes( (At present only document references can be structured). |

| : List | On the right-hand side is the list of document references. The local document references are marked with the little house symbol ( link: Description of the buttons for maintaining the assignments to the document references |

| Description of structure node | For the folder (structure nodes) defined in the structure tree, a different description can be entered here and saved using the save button to the right of the field. |

| preliminary calculations | |

| In this tab you can see the preliminary calculations already made for the part. You can also create a new preliminary calculation directly from this window using the "New preliminary calculation" button. If the "Transient" check mark is set, a transient preliminary calculation is created that is not saved in the database. Rows can be dropped directly into the list from the conditional table defined via specifications in order to trigger a precalculation. | |

| : New preliminary costing | A new precalculation is created (see also field "Transient"). |

| : Transient | If the button "New pre-calculation" is pressed a new pre-calculation is created either transient (will not be saved) or persistent (will be saved). |

| Context menu on the list of precalculations | see |

| button | Description | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Production data | |||||||||||||||||||||||

| Parts list | |||||||||||||||||||||||

| Work plan | |||||||||||||||||||||||

| Features | |||||||||||||||||||||||

| Create | |||||||||||||||||||||||

| Insert | |||||||||||||||||||||||

| Remove | |||||||||||||||||||||||

| Costs | |||||||||||||||||||||||

| Type of cost | |||||||||||||||||||||||

| Documents | |||||||||||||||||||||||

| Open | Opens the document of the selected document reference in the preview. Depending on the file type, Adobe Acrobat Reader, Word or, for example, Internet Explorer is started. | ||||||||||||||||||||||

| Insert | When inserting, you can choose between local document references and global document references.

| ||||||||||||||||||||||

| preliminary calculation | |||||||||||||||||||||||

| New preliminary costing | |||||||||||||||||||||||

| Specifications | With this button it is possible to store combinations of characteristics in the form of specification numbers for which the preliminary costing is to be carried out automatically. (context menu see here) | ||||||||||||||||||||||

| Status bar | |||||||||||||||||||||||

| OK | Changes to the production part are saved. If no changes have been made, the button is locked. | ||||||||||||||||||||||

| New | The input window is cleared. | ||||||||||||||||||||||

| Delete | The displayed production part is deleted. | ||||||||||||||||||||||

| Close | The window is closed without saving changes. If you want to save the changes, you must press the "OK" button. | ||||||||||||||||||||||

List window

Serves to list the production parts.

| Menu item | Description |

|---|---|

| Edit | - |

| new | - |

| : : Production part | Create new production part |

| : : Production Service | Create new service production |

| Options | Call up the option window |

| Symbol | Description |

|---|---|

| The input window is cleared. |

| Machining a production part |

| Delete production part |

| Printing the window content |

| Search for material characteristics. This searches the attributes of the roll and part, with the attribute settings of the roll predominant if they are different | |

| Search for objects that do not contain any of the characteristics to be specified (regardless of the value set) | |

| Empty list and delete search terms | |

| Create/edit notes |

| Call up the maintenance mask of the part |

| Call up the maintenance mask of the parts list of the production part |

| Call up the maintenance mask of the routing of the production part |

| Display of all operations of the production part |

| Set validity |

| Field | Description |

|---|---|

| Number | Production part number |

| Search Keyword | Search term (of the parts master) |

| Type of cost | Type of cost |

| button | Description |

|---|---|

| Edit | The current production part is displayed in the input window. |

| New | An empty input window opens. |

| Delete | The selected production part is deleted. |

| Close | The window is closed. |

Selection window

This window is used to select a production part.

| Menu item | Description |

|---|---|

| Options | Call up the option window |

| Field | Description |

|---|---|

| Number | Production part number |

| Search Keyword | Search term (of the parts master) |

| Type of cost | Type of cost |

| button | Description |

|---|---|

| OK | The selected production part is transferred. |

| Close | The selection is cancelled. |

Option window

All settings for the search can be made here. The window can only be closed with the "OK" button.

| Menu item | Description |

|---|---|

| Edit | - |

| : Set default settings | all changed settings are reset to default |

| Field | Description |

|---|---|

| List options | |

| : Search options | - |

| : : : Immediate take over in case of a hit | If only one production part is found during a search, this is opened in the input window |

| : : : Clear list before new search | The list is cleared before each new search |

| : : General search | Use search terms from the production part itself |

| : : Advanced search | Search terms of the other roles of the production part are taken into account |

| : Validity | Validity |

| : Number of objects | Determines the maximum number of objects in the list that can be displayed during a search |

| Editing options | |

| : Presentation of preliminary costing | |

| : : Standard list | Here you can define the list format for the list of preliminary calculations. For this purpose a report must be selected which has its own column definition. |

| button | Description |

|---|---|

| OK | The settings are saved and the window is closed. |

Production cost allocation or calculation

As a matter of principle, the production costs for a part are divided into two cost areas that are valued differently:

Wage costs and material costs.

The costs of a production part, taking into account all the necessary wage and material costs on the basis of the master parts lists and routings, are taken over by the preliminary parts calculation.

As a standard, the additional costs incurred in addition to wages and materials, e.g. for purchasing or stock management of the required parts, are included in the overheads. These are stored globally in the client.

However, the following approach is preferable in order to be able to calculate production costs precisely according to other costs incurred during production, such as machine running costs and programming costs, without having to include all costs invisibly in overheads:

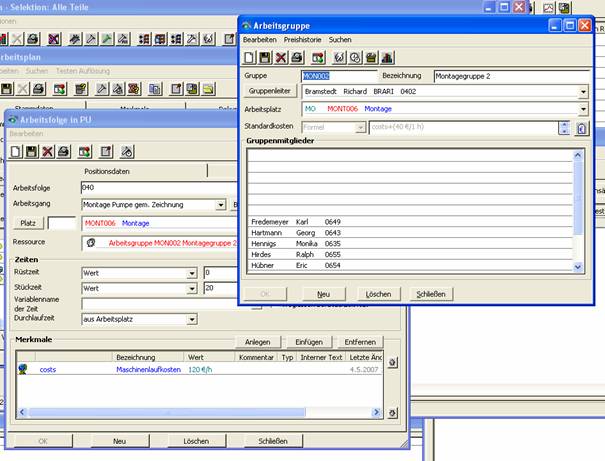

In the part or at the work plan position, a material characteristic must be defined which contains the costs for e.g. the machine costs per hour according to the following format

costs = 120€/h (see below in the picture in the work sequence).

You must therefore create a material characteristic for each cost element.

The characteristic can also be stored directly on variant parts and can also calculate itself there from other boundary conditions (calculated or conditional characteristics).

To be able to take these costs into account, a formula in the resource of the work sequence is necessary (in the picture the standard costs of the working group):

Standard costs = formula = costs+(40€/1h)

Since the formulae do not know any compound units, instead of 40€/h --> write 40€/1h and put this in brackets.

The machine costs per hour specified via the material characteristic are now added to the standard machine costs per hour.

In order to check whether the costs are actually there without any error occurring, the formula can be extended by a query as follows

(if(has(costs))costs else (0?))+(40€/1h)

In this case, the system queries in advance whether the costs have been found and otherwise uses the value 0?, whose unit is based on the next component for further calculation.

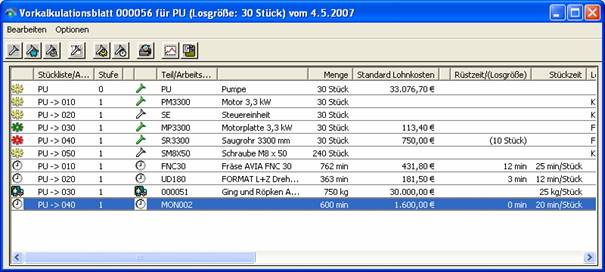

In the preliminary parts calculation we then immediately see the result:

The marked line is our work sequence, which has received wage costs of 1.600€ for 600 minutes (10 hours) (120€ machine running costs + 40€ standard costs = 160€ per hour * 10 hours = 1600€)

Related topics

- Index

- Work plan

- Attributes

- Development section

- Parts list

- Part master data

- Parts preliminary costing

Technical documentation

Overview

Has changed:

product.mod

Production part basic module

Module name

product.mod

Classes

Security

In addition to restricting access rights via the class and its data fields, the module can be restricted in its use via some of the received messages.

| Message | Parameters | Function | Security |

|---|---|---|---|

| LIMIT_SET | |||

| PRODUCT_CHANGED | Production part object | Production part was changed | |

| PRODUCT_CREATED | Production part object | Production part was created | |

| PRODUCT_DELETED | Production part object | Production part was deleted |

| Message | Parameters | Function | Receiver module |

|---|---|---|---|

| EDIT_PRODUCT | NULL or production part object | Call up input window for production part | Production part editing module |

| SET_LIMIT |

Development part selection module

Module name

devel.mod

Classes

Security

In addition to restricting access rights via the class and its data fields, the module can be restricted in its use via some of the received messages.

| Message | Parameters | Function | Security |

|---|---|---|---|

| LIMIT_SET | |||

| PRODUCT_CHANGED | Production part object | Production part was changed | |

| PRODUCT_CREATED | Production part object | Production part was created | |

| PRODUCT_DELETED | Production part object | Production part was deleted | |

| SELECT_DEVELOPMENT_ITEM |

| Message | Parameters | Function | Receiver module |

|---|---|---|---|

| DEVELOPMENT_ITEM_SELECTED | |||

| EDIT_PRODUCT | NULL or production part object | Call up input window for production part | Production part editing module |

| SET_LIMIT |

Production part editing module

Module name

produedt.mod

Classes

Security

In addition to restricting access rights via the class and its data fields, the module can be restricted in its use via some of the received messages.

| Message | Parameters | Function | Security |

|---|---|---|---|

| ATTRIBUTE_SELECTED | |||

| BILL_OF_MATERIAL_SELECTED | |||

| COMMENT_CHANGED | Object | Comment has been changed | |

| CONDITIONED_ATTRIBUTE_CREATED | |||

| EDIT_PRODUCT | NULL or production part object | Call up input window for production part | |

| FORMULA_ATTRIBUTE_CREATED | |||

| JOB_SCHEDULE_SELECTED | |||

| LIMIT_SET | |||

| LIST_PRODUCT | Collection production part objects or NULL | Open list window for production part | |

| LOAD_PRODUCT | Import production part | ||

| PRICE_DISCOUNT_CHANGED | |||

| PRICE_TABLE_CREATED | |||

| PRICE_TABLE_DELETED | |||

| PRODUCT_CHANGED | Production part object | Production part was changed | |

| PRODUCT_CREATED | Production part object | Production part was created | |

| PRODUCT_DELETED | Production part object | Production part was deleted | |

| SET_ALLOCATION_CREATED | |||

| SLOT_ATTRIBUTE_CREATED | |||

| STRUCTURE_SELECTED | |||

| UNIT_SELECTED | |||

| PRODUCT_COSTS_SECURITY | none | If this message is blocked for the logged-in user, he cannot access the cost and pre-calculation tabs. He cannot therefore see what a production part costs. | |

| Message | Parameters | Function | Receiver module |

|---|---|---|---|

| ASK_YES_NO | |||

| CREATE_PRICE_TABLE | |||

| DELETE_PRICE_TABLE | |||

| EDIT_BILL_OF_MATERIAL | |||

| EDIT_COMMENT | Object | Open the input window for comments | Comment editing module |

| EDIT_ITEM | NULL or part root object | Calling up the input window for part trunks | Part master editing module |

| EDIT_JOB_SCHEDULE | |||

| EDIT_PRICE_DISCOUNT | |||

| EDIT_PRICE_TABLE | |||

| EDIT_PROCEEDINGS | NULL or operation object | Call up the input window for operations | Process editing module |

| EDIT_PRODUCT | NULL or production part object | Call up input window for production part | Production part editing module |

| EDIT_UNIT_TABLE | |||

| EDIT_VALIDITY_BY_DATE | Window title, object, recipient of the reply | Call up the input window for validity | Validity Editing Module |

| LIST_PRODUCT | NULL or Collection production part objects | Open list window for production part | Production part editing module |

| PRODUCT_CHANGED | Production part object | Production part was changed | |

| PRODUCT_CREATED | Production part object | Production part was created | |

| PRODUCT_DELETED | Production part object | Production part was deleted | |

| SELECT_ATTRIBUTES | |||

| SELECT_BILL_OF_MATERIAL | |||

| SELECT_JOB_SCHEDULE | |||

| SELECT_STRUCTURE | |||

| SET_LIMIT | |||

| SHOW_PREVIEW | Widget | Print Preview | Print Preview |

| UNIT_SELECTED |

Development part Editing module

Module name

develedt.mod

Classes

Security

In addition to restricting access rights via the class and its data fields, the module can be restricted in its use via some of the received messages.

| Message | Parameters | Function | Security |

|---|---|---|---|

| ATTRIBUTE_SELECTED | |||

| BILL_OF_MATERIAL_SELECTED | |||

| COMMENT_CHANGED | Object | Comment has been changed | |

| CONDITIONED_ATTRIBUTE_CREATED | |||

| DEVELOPMENT_ITEM_DELETED | |||

| EDIT_DEVELOPMENT_ITEM | |||

| EDIT_PRODUCT | NULL or production part object | Call up input window for production part | |

| EMPLOYEE_SELECTED | |||

| FORMULA_ATTRIBUTE_CREATED | |||

| JOB_SCHEDULE_SELECTED | |||

| LIMIT_SET | |||

| LIST_DEVELOPMENT_ITEM | |||

| LIST_PRODUCT | Collection production part objects or NULL | Open list window for production part | |

| LOAD_DEVELOPMENT_ITEM | |||

| LOAD_PRODUCT | Import production part | ||

| PRICE_DISCOUNT_CHANGED | |||

| PRICE_TABLE_CREATED | |||

| PRICE_TABLE_DELETED | |||

| PRODUCT_CHANGED | Production part object | Production part was changed | |

| PRODUCT_CREATED | Production part object | Production part was created | |

| PRODUCT_DELETED | Production part object | Production part was deleted | |

| SET_ALLOCATION_CREATED | |||

| SLOT_ATTRIBUTE_CREATED | |||

| STRUCTURE_SELECTED | |||

| UNIT_SELECTED |

| Message | Parameters | Function | Receiver module |

|---|---|---|---|

| ASK_YES_NO | |||

| CREATE_PRICE_TABLE | |||

| DELETE_PRICE_TABLE | |||

| DEVELOPMENT_ITEM_CHANGED | |||

| DEVELOPMENT_ITEM_CREATED | |||

| DEVELOPMENT_ITEM_DELETED | |||

| EDIT_BILL_OF_MATERIAL | |||

| EDIT_COMMENT | Object | Open the input window for comments | Comment editing module |

| EDIT_DEVELOPMENT_ITEM | |||

| EDIT_ITEM | |||

| EDIT_JOB_SCHEDULE | |||

| EDIT_PRICE_DISCOUNT | |||

| EDIT_PRICE_TABLE | |||

| EDIT_PROCEEDINGS | NULL or operation object | Call up the input window for operations | Process editing module |

| EDIT_PRODUCT | NULL or production part object | Call up input window for production part | Production part editing module |

| EDIT_UNIT_TABLE | |||

| EDIT_VALIDITY_BY_DATE | Window title, object, recipient of the reply | Call up the input window for validity | Validity Editing Module |

| LIST_DEVELOPMENT_ITEM | |||

| LIST_PRODUCT | Open list window for production part | Production part editing module | |

| PRODUCT_CHANGED | Production part object | Production part was changed | |

| PRODUCT_CREATED | Production part object | Production part was created | |

| PRODUCT_DELETED | Production part object | Production part was deleted | |

| SELECT_ATTRIBUTES | |||

| SELECT_BILL_OF_MATERIAL | |||

| SELECT_EMPLOYEE | |||

| SELECT_JOB_SCHEDULE | |||

| SELECT_STRUCTURE | |||

| SET_LIMIT | |||

| SHOW_PREVIEW | Widget | Print Preview | Print Preview |

| UNIT_SELECTED |

Production part selection module

Module name

produsel.mod

Classes

Security

In addition to restricting access rights via the class and its data fields, the module can be restricted in its use via some of the received messages.

| Message | Parameters | Function | Security |

|---|---|---|---|

| LIMIT_SET | |||

| PRODUCT_CHANGED | Production part object | Production part was changed | |

| PRODUCT_CREATED | Production part object | Production part was created | |

| PRODUCT_DELETED | Production part object | Production part was deleted | |

| SELECT_PRODUCT | Collection production part objects or NULL, recipient of the response | Call up selection window for production part |

| Message | Parameters | Function | Receiver module |

|---|---|---|---|

| EDIT_PRODUCT | NULL or production part object | Call up input window for production part | Production part editing module |

| PRODUCT_SELECTED | Production part object, recipient | Production part was selected | |

| SET_LIMIT |